Lead-lined Galvanized Pipe -- A Lurking Danger for Homeowners and Utilities

In much of the eastern part of the US, particularly in New England, the galvanized iron used for service lines was often lead-lined. For all intents, these behave like lead pipes. They form lead-based corrosion scales and they yield dissolved and particulate lead in the same ways that pure lead pipes do. Hence they constitute a hidden peril for the unsuspecting homeowner.

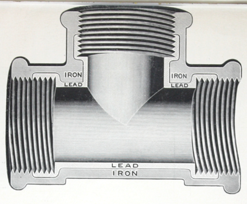

George W Harrington obtained a patent in 1892 for his invention of lead and tin lined iron pipe. He founded the “Lead Lined Iron Pipe” Company, which began operations in Wakefield MA in 1893. Thomas Dwyer joined the company soon after and became head of marketing and then general manager. He vigorously and succesfully promoted the company's products. Their marketing stressed the usefulness of their pipes for water service branches; the plant was producing 4 million feet per year by 1904. From articles in the trade press, it is known that service lines with this construction were installed in over 200 municipalities as of 1904. Specifically mentioned are the following distribution systems:

| Installations of lead-lined galvanized services | |||||

| State | Town | Source | |||

| MA | Lowell | Lynn | Lawrence | Quincy | F&WE |

| MA | Cambridge | Springfield | US EPA | ||

| MA | |||||

| MD | Baltimore | F&WE | |||

| NY | NYC | Utica | F&WE | ||

| NJ | Atlantic City | Totowah (Patterson) | F&WE; LNP | ||

| OH | Columbus | E. Liverpool | F&WE; LNP | ||

| PA | Scranton | Indiana | Reading | LNP | |

| RI | Pawtuckett | F&WE | |||

| NH | Manchester | F&WE | |||

| Lead-lined pipes not permitted or not used | |||||

| DC | Washington | LNP | |||

| NJ | Patterson | LNP | |||

| F&WE = Fire and Water Engineering; LNP = Local newspaper, USEPA = Water Supply & Water Resources Division | |||||

In addition, the Massachusetts Board of Health in 1905 became concerned about lead poisoning from service lines and conducted a survey of types of service lines in each town. Seventeen reported significant numbers of lead-lined services.

| 1905 Annual Report Mass State Board of Health | ||||

| Inventory of service lines in state (p.197-205) | ||||

| Number of lead-lined iron services | ||||

| Andover | 316 | N. Attleborough | 220 | |

| Beverly | 172 | Reading | 724 | |

| Easton | 300 | Revere | 150 | |

| Lawrence | 962 | Somerville | 2000 | |

| Lynn | 1600 | Stoneham | 800 | |

| Marlborough | 200 | Wakefield | 170 | |

| Maynard | 100 | Worcester | 1800 | |

| Milbury | 245 | Woburn | 200 | |

| N. Andover | 150 | |||

Eau Claire WI has also reported having numerous lead-lined galvanized service branches:

Some examples of advertising images by the Lead Lined Iron Pipe Co. Click on an image for a larger version.

|

|

|

|

|

|

|

These pipes accumulate lead-rich corrosion scales in much the same way as pure lead pipes. Below are averages of analyses of a set of scales from lead and lead-lined service lines from utilities in the northeastern US

Group 1: Major Constituents, % |

|||||||||

Type |

Layer |

Pb |

Fe |

Al |

Ca |

Cu |

Zn |

P |

Mn |

Lead |

L1 |

33.3 |

4.56 |

2.88 |

0.60 |

0.09 |

0.29 |

0.60 |

0.03 |

Lead |

L2 |

44.0 |

0.99 |

0.92 |

0.33 |

0.02 |

0.12 |

0.36 |

0.02 |

Lead-lined |

L1 |

31.2 |

9.48 |

2.36 |

0.58 |

0.06 |

0.63 |

0.57 |

0.10 |

Lead-lined |

L2 |

42.1 |

2.27 |

1.10 |

0.40 |

0.03 |

0.35 |

0.58 |

0.03 |

; L1 = surface layer; L2 = bottom layer, closest to pipe |

|||||||||

Group 2: Minor constituents, mg/kg |

||||||||||||

Type |

Layer |

As |

Ba |

Bi |

Cd |

Co |

Cr |

Ni |

Sb |

Sn |

Sr |

V |

Lead |

L1 |

60 |

135 |

208 |

1.3 |

2.9 |

57 |

26 |

15 |

44 |

38 |

1280 |

Lead |

L2 |

19 |

61 |

169 |

0.9 |

0.6 |

37 |

10 |

25 |

27 |

21 |

999 |

Lead-lined |

L1 |

39 |

144 |

179 |

48 |

7.9 |

246 |

92 |

13 |

126 |

39 |

1310 |

Lead-lined |

L2 |

29 |

72 |

126 |

82 |

1.8 |

93 |

8 |

15 |

131 |

21 |

2060 |

Values in bold are significantly higher in samples from galvanized than from lead only service lines |

||||||||||||